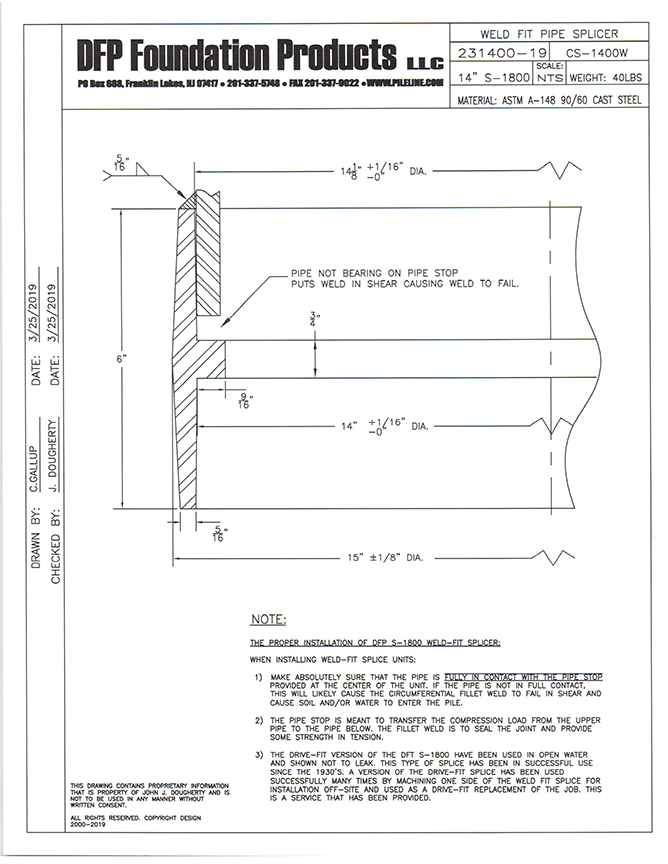

The Proper way to install the DFP S-1800 Weld-Fit Splices

by Jack Dougherty

When installing Weld-fit splice units.

Make absolutely sure that the pipe is fully in contact with the pipe stop provided at the center of the unit. If the pipe is not in full contact, this will likely to cause the circumferential fillet weld to fail in shear and cause soil and or water to enter the pile.

The pipe stop is meant to transfer the compression load from the upper pipe to the pipe below. The fillet weld is to seal the joint and provide some strength in tension.

The drive-fit version of the DFP S-1800 have been used in open water and shown not to leak. This type of splice has been in successful use since the 1930’s. A version of the drive-fit splice has been many times successfully used by machining one side weld-fit for installation off-site and used as drive-fit on the job. This is a service we have provided.

Click on the photo below to see the full sized drawing.

© Copyright 2019 Pileline

Publishing